| Availability: | |

|---|---|

| Quantity: | |

BA-40 BA-60 BA-80 BA-110 BA-135

BETA

Automatic One-Step Three Position Injection Blow Hollow Molding Machine PE PP Small Bottle Making Machine

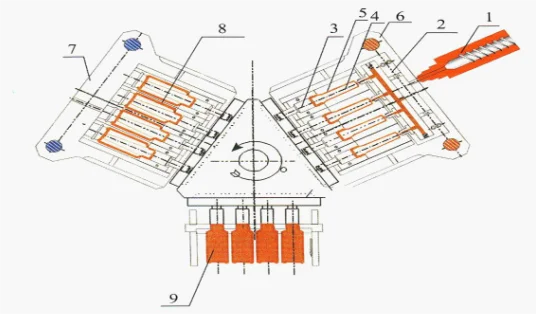

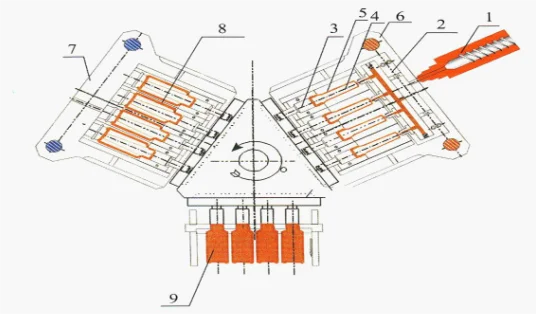

EQUIPMENT PRODUCTIVE FLOW SHEET

Automatic One-Step Three Position Injection Blow Hollow Molding Machine PE PP Small Bottle Making Machine

EQUIPMENT PRODUCTIVE FLOW SHEET

Item | Unit | BA-40 | BA-60 | BA-80 | BA-110 | BA-135 |

Injection System | ||||||

Screw Diameter | mm | 40 | 45 | 55 | 65 | 70 |

Screw L/D | % | 21:1 | 22:1 | 22:1 | 22:1 | 22:1 |

Injection weight | g | 140 | 260 | 534 | 630 | 650 |

Heating power | KW | 14 | 14 | 20 | 22 | 30 |

Number of barrel zone | / | 3+N | 3+N | 5+N | 6+N | 6+N |

Injection stroke | mm | 120 | 160 | 160 | 200 | 200 |

Clamping System | ||||||

Clamping force of injection | KN | 400 | 600 | 800 | 1100 | 1350 |

Opening stroke for injection | mm | 140 | 140 | 140 | 140 | 140 |

Clamping force of blowing | KN | 60 | 100 | 120 | 150 | 200 |

Opening stroke for blowing | mm | 140 | 140 | 140 | 140 | 140 |

Lifting height of rotary table | mm | 70 | 70 | 70 | 70 | 70 |

Mould | ||||||

Max.Platen size(L × W) | mm | 480×340 | 600×390 | 800×400 | 1100×460 | 1300×500 |

Mold thickness | mm | 180 | 240 | 280 | 280 | 280 |

Bottle max diameter | mm | 120 | 120 | 120 | 120 | 120 |

Bottle max height | mm | 220 | 220 | 220 | 220 | 220 |

Bottle max volume | mm | 1-1000 | 1-1000 | 1-1000 | 1-1000 | 1-1000 |

Stripping stroke | mm | 220 | 230 | 230 | 260 | 280 |

Hydraulic system | ||||||

Hydraulic Pressure | Map | 14 | 14 | 14 | 14 | 14 |

Motor power | KW | 15 | 22 | 22+22 | 37+37 | 37+37 |

Dry cycle | s | 4 | 4 | 4 | 4 | 4 |

Total Power | KW | 30 | 37 | 70 | 90 | 95 |

Operating power | % | 52-70 | 52-70 | 52-70 | 52-70 | 52-70 |

Others | ||||||

Min.Air pressure of compressed air | MPa | 0.7-1.2 | 0.7-1.2 | 0.7-1.2 | 0.7-1.2 | 0.7-1.2 |

Compressed air capacity | M³/min | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 |

Water flowage | M³/h | 4 | 4 | 4 | 4 | 4 |

Cooling water pressure | MPa | 0.3-0.4 | 0.3-0.4 | 0.3-0.4 | 0.3-0.4 | 0.3-0.4 |

Dimension(L× W× H) | M | 3.5×1.4×1.9 | 3.5×1.4×1.8 | 4.5×1.6×2 | 5×1.8×2.2 | 5.5×2×2.4 |

Net weight | Ton | 4 | 5 | 10 | 17 | 18 |

Item | Unit | BA-40 | BA-60 | BA-80 | BA-110 | BA-135 |

Injection System | ||||||

Screw Diameter | mm | 40 | 45 | 55 | 65 | 70 |

Screw L/D | % | 21:1 | 22:1 | 22:1 | 22:1 | 22:1 |

Injection weight | g | 140 | 260 | 534 | 630 | 650 |

Heating power | KW | 14 | 14 | 20 | 22 | 30 |

Number of barrel zone | / | 3+N | 3+N | 5+N | 6+N | 6+N |

Injection stroke | mm | 120 | 160 | 160 | 200 | 200 |

Clamping System | ||||||

Clamping force of injection | KN | 400 | 600 | 800 | 1100 | 1350 |

Opening stroke for injection | mm | 140 | 140 | 140 | 140 | 140 |

Clamping force of blowing | KN | 60 | 100 | 120 | 150 | 200 |

Opening stroke for blowing | mm | 140 | 140 | 140 | 140 | 140 |

Lifting height of rotary table | mm | 70 | 70 | 70 | 70 | 70 |

Mould | ||||||

Max.Platen size(L × W) | mm | 480×340 | 600×390 | 800×400 | 1100×460 | 1300×500 |

Mold thickness | mm | 180 | 240 | 280 | 280 | 280 |

Bottle max diameter | mm | 120 | 120 | 120 | 120 | 120 |

Bottle max height | mm | 220 | 220 | 220 | 220 | 220 |

Bottle max volume | mm | 1-1000 | 1-1000 | 1-1000 | 1-1000 | 1-1000 |

Stripping stroke | mm | 220 | 230 | 230 | 260 | 280 |

Hydraulic system | ||||||

Hydraulic Pressure | Map | 14 | 14 | 14 | 14 | 14 |

Motor power | KW | 15 | 22 | 22+22 | 37+37 | 37+37 |

Dry cycle | s | 4 | 4 | 4 | 4 | 4 |

Total Power | KW | 30 | 37 | 70 | 90 | 95 |

Operating power | % | 52-70 | 52-70 | 52-70 | 52-70 | 52-70 |

Others | ||||||

Min.Air pressure of compressed air | MPa | 0.7-1.2 | 0.7-1.2 | 0.7-1.2 | 0.7-1.2 | 0.7-1.2 |

Compressed air capacity | M³/min | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 |

Water flowage | M³/h | 4 | 4 | 4 | 4 | 4 |

Cooling water pressure | MPa | 0.3-0.4 | 0.3-0.4 | 0.3-0.4 | 0.3-0.4 | 0.3-0.4 |

Dimension(L× W× H) | M | 3.5×1.4×1.9 | 3.5×1.4×1.8 | 4.5×1.6×2 | 5×1.8×2.2 | 5.5×2×2.4 |

Net weight | Ton | 4 | 5 | 10 | 17 | 18 |