| Speed: | |

|---|---|

| Application: | |

| Certification: | |

| Cooling method: | |

| Availability: | |

| Quantity: | |

Screw type air compressor

BETA PLASTIC MACHINERY

8414301900

| Parameter | Oil-Injected Model | Oil-Free Model |

|---|---|---|

| Airflow (CFM) | 100 - 1000 | 50 - 500 |

| Pressure (PSI) | 80 - 150 | 80 - 150 |

| Power (HP) | 10 - 300 | 10 - 200 |

| Noise Level (dB) | 65 - 75 | 70 - 80 |

| Maintenance Cost | Low | Moderate |

| Air Quality | Good | Excellent |

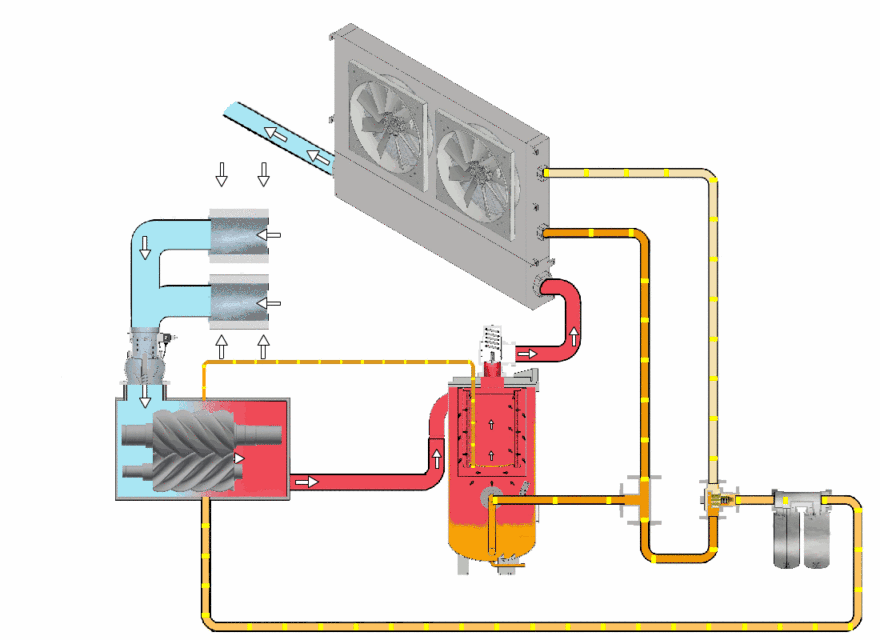

Working principle

Control: The operation of the screw air compressor is controlled by a control system, which monitors and adjusts various parameters such as pressure, temperature, and flow rate. This ensures that the compressor operates efficiently and safely.

Lubrication: The rotating screws and other moving parts of the screw air compressor require lubrication to reduce friction and wear. This is typically achieved by injecting oil into the compression chamber or using an oil bath system.

Cooling: The compression process generates heat, so the screw air compressor is equipped with cooling mechanisms to prevent overheating. This can include air or water cooling systems that remove excess heat from the compressor.

Maintenance: Regular maintenance is essential to ensure the optimal performance and longevity of a screw air compressor. This includes tasks such as oil changes, filter replacements, and inspection of components for wear or damage.

Energy Efficiency: Screw air compressors are designed to be energy efficient, as they can consume a significant amount of electricity. Various measures, such as variable speed drives and energy recovery systems, are implemented to reduce energy consumption and minimize operating costs.

Applications: Screw air compressors are widely used in various industries for tasks such as powering pneumatic tools, supplying compressed air to manufacturing processes, and providing air for HVAC systems. They are preferred for their high efficiency, reliability, and versatility.

| Parameter | Oil-Injected Model | Oil-Free Model |

|---|---|---|

| Airflow (CFM) | 100 - 1000 | 50 - 500 |

| Pressure (PSI) | 80 - 150 | 80 - 150 |

| Power (HP) | 10 - 300 | 10 - 200 |

| Noise Level (dB) | 65 - 75 | 70 - 80 |

| Maintenance Cost | Low | Moderate |

| Air Quality | Good | Excellent |

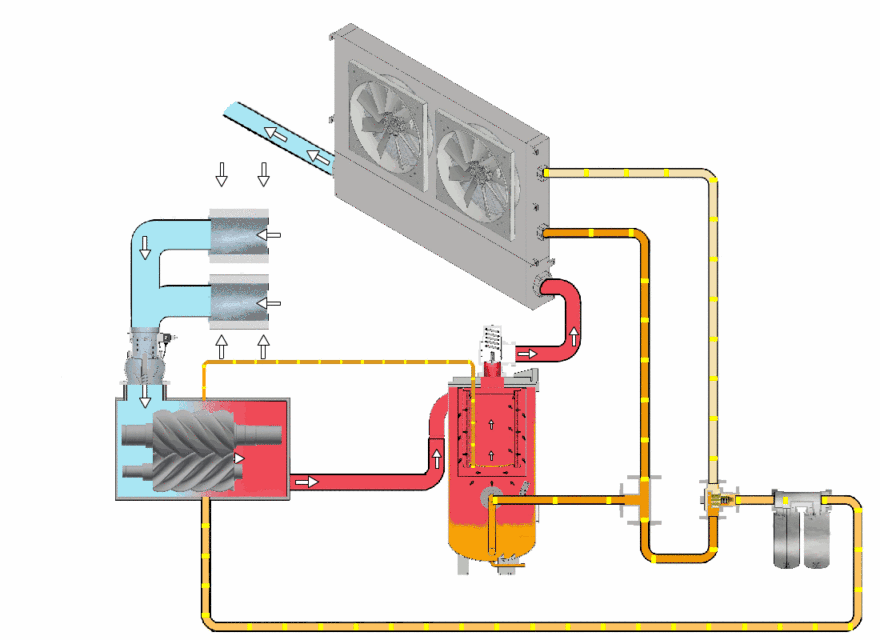

Working principle

Control: The operation of the screw air compressor is controlled by a control system, which monitors and adjusts various parameters such as pressure, temperature, and flow rate. This ensures that the compressor operates efficiently and safely.

Lubrication: The rotating screws and other moving parts of the screw air compressor require lubrication to reduce friction and wear. This is typically achieved by injecting oil into the compression chamber or using an oil bath system.

Cooling: The compression process generates heat, so the screw air compressor is equipped with cooling mechanisms to prevent overheating. This can include air or water cooling systems that remove excess heat from the compressor.

Maintenance: Regular maintenance is essential to ensure the optimal performance and longevity of a screw air compressor. This includes tasks such as oil changes, filter replacements, and inspection of components for wear or damage.

Energy Efficiency: Screw air compressors are designed to be energy efficient, as they can consume a significant amount of electricity. Various measures, such as variable speed drives and energy recovery systems, are implemented to reduce energy consumption and minimize operating costs.

Applications: Screw air compressors are widely used in various industries for tasks such as powering pneumatic tools, supplying compressed air to manufacturing processes, and providing air for HVAC systems. They are preferred for their high efficiency, reliability, and versatility.

| Model | Power (KW) | Exhaust volume(m³/min) | Exhaust pressure(Bar) | Noise(Dba) | Weight(Kg) | Dimension (L*W*H)mm |

| BETA-22 | 22 | 6.5 | 3.0 | 62±3 | 1330 | 1415*1030*1330 |

| BETA-37 | 37 | 11.7 | 3.0 | 64±3 | 1420 | 2160*1400*1750 |

| BETA-55 | 55 | 17.2 | 3.0 | 62±3 | 2100 | 2160*1400*1750 |

| BETA-75 | 75 | 24.4 | 3.0 | 65±3 | 2830 | 2160*1400*1750 |

| BETA-90 | 90 | 30.3 | 3.0 | 67±3 | 3800 | 2900*1830*2000 |

| BETA-110 | 110 | 36.8 | 3.0 | 69±3 | 4600 | 2900*1830*2000 |

| BETA-132 | 132 | 48.0 | 3.0 | 71±3 | 5000 | 3400*2050*2250 |

| BETA-160 | 160 | 43.2 | 3.0 | 72±3 | 6200 | 3400*2050*2250 |

| BETA-185 | 185 | 64.5 | 3.0 | 73±3 | 7000 | 4250*2280*2550 |

| BETA-200 | 200 | 70.9 | 3.0 | 73±3 | 8000 | 4250*2280*2550 |

| Model | Power (KW) | Exhaust volume(m³/min) | Exhaust pressure(Bar) | Noise(Dba) | Weight(Kg) | Dimension (L*W*H)mm |

| BETA-22 | 22 | 6.5 | 3.0 | 62±3 | 1330 | 1415*1030*1330 |

| BETA-37 | 37 | 11.7 | 3.0 | 64±3 | 1420 | 2160*1400*1750 |

| BETA-55 | 55 | 17.2 | 3.0 | 62±3 | 2100 | 2160*1400*1750 |

| BETA-75 | 75 | 24.4 | 3.0 | 65±3 | 2830 | 2160*1400*1750 |

| BETA-90 | 90 | 30.3 | 3.0 | 67±3 | 3800 | 2900*1830*2000 |

| BETA-110 | 110 | 36.8 | 3.0 | 69±3 | 4600 | 2900*1830*2000 |

| BETA-132 | 132 | 48.0 | 3.0 | 71±3 | 5000 | 3400*2050*2250 |

| BETA-160 | 160 | 43.2 | 3.0 | 72±3 | 6200 | 3400*2050*2250 |

| BETA-185 | 185 | 64.5 | 3.0 | 73±3 | 7000 | 4250*2280*2550 |

| BETA-200 | 200 | 70.9 | 3.0 | 73±3 | 8000 | 4250*2280*2550 |