| Material: | |

|---|---|

| Capacity: | |

| Pressure: | |

| Availability: | |

| Quantity: | |

Air-cooled dryer; Water-cooled dryer

BETA PLASTIC MACHINERY

8418692090

Air Dryer Refrigerated Air Drying Machine For Air Compressor

1. Working principle

The humid and high-temperature compressed air flows into the pre-cooler to dissipate heat and then flows into the heat exchanger to exchange heat with the cold air discharged from the evaporator, thereby reducing the temperature of the compressed air entering the evaporator.

The heat-exchanged compressed air flows into the evaporator and exchanges heat with the refrigerant through the heat exchange function of the evaporator. The heat in the compressed air is taken away by the refrigerant, and the compressed air is rapidly cooled.The moisture in the humid air condenses quickly when it reaches the saturation temperature. The condensed moisture forms water droplets after condensation. After the unique air-water separator rotates at high speed, the moisture is separated from the air due to centrifugal force. After separation, the water is discharged from the automatic drain valve.The air pressure dew point after cooling can reach a minimum of 2℃

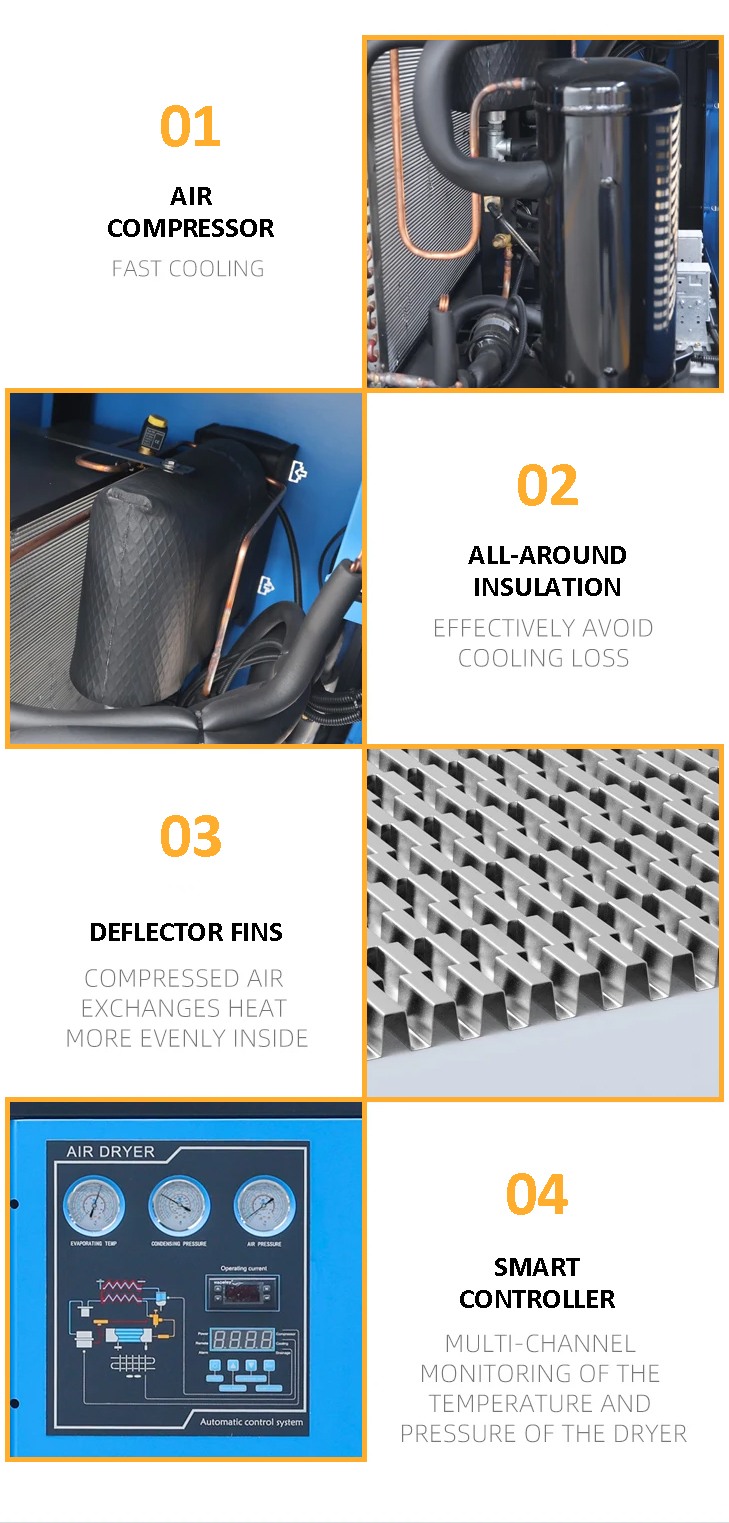

2. Product characteristics

- Adopt special design, make it small pressure difference and energy saving.

- Use thickened copper tubes to prevent corrosion and leakage of the copper tubes, extending service life.

- Using high performance heat exchanger.

- The design margin of the entire machine is increased by 20% to ensure stable operation of the unit under harsh working conditions.

- The cylinder is coated with anti-rust paint to prevent rust inside the machine.

- Use high quality parts

- The air-water separator and multiple drainage designs enable more timely and thorough drainage, avoiding the problem of poor dew point quality caused by residual moisture.

- Low-pressure protection device effectively protects compressor life and reduces maintenance costs.

| Product Name | Stainless steel air tank |

| Volume | 300-6000L; 0.3-6m³ |

| Pressure | 8-16 bar |

| Applicable Industrial | Air compressor |

| Medium | air, steam, nitrogen, oxygen, water |

| Air Inlet Temperature | ≤60℃ |

| Service Life | 10-15 years |

Air Dryer Refrigerated Air Drying Machine For Air Compressor

1. Working principle

The humid and high-temperature compressed air flows into the pre-cooler to dissipate heat and then flows into the heat exchanger to exchange heat with the cold air discharged from the evaporator, thereby reducing the temperature of the compressed air entering the evaporator.

The heat-exchanged compressed air flows into the evaporator and exchanges heat with the refrigerant through the heat exchange function of the evaporator. The heat in the compressed air is taken away by the refrigerant, and the compressed air is rapidly cooled.The moisture in the humid air condenses quickly when it reaches the saturation temperature. The condensed moisture forms water droplets after condensation. After the unique air-water separator rotates at high speed, the moisture is separated from the air due to centrifugal force. After separation, the water is discharged from the automatic drain valve.The air pressure dew point after cooling can reach a minimum of 2℃

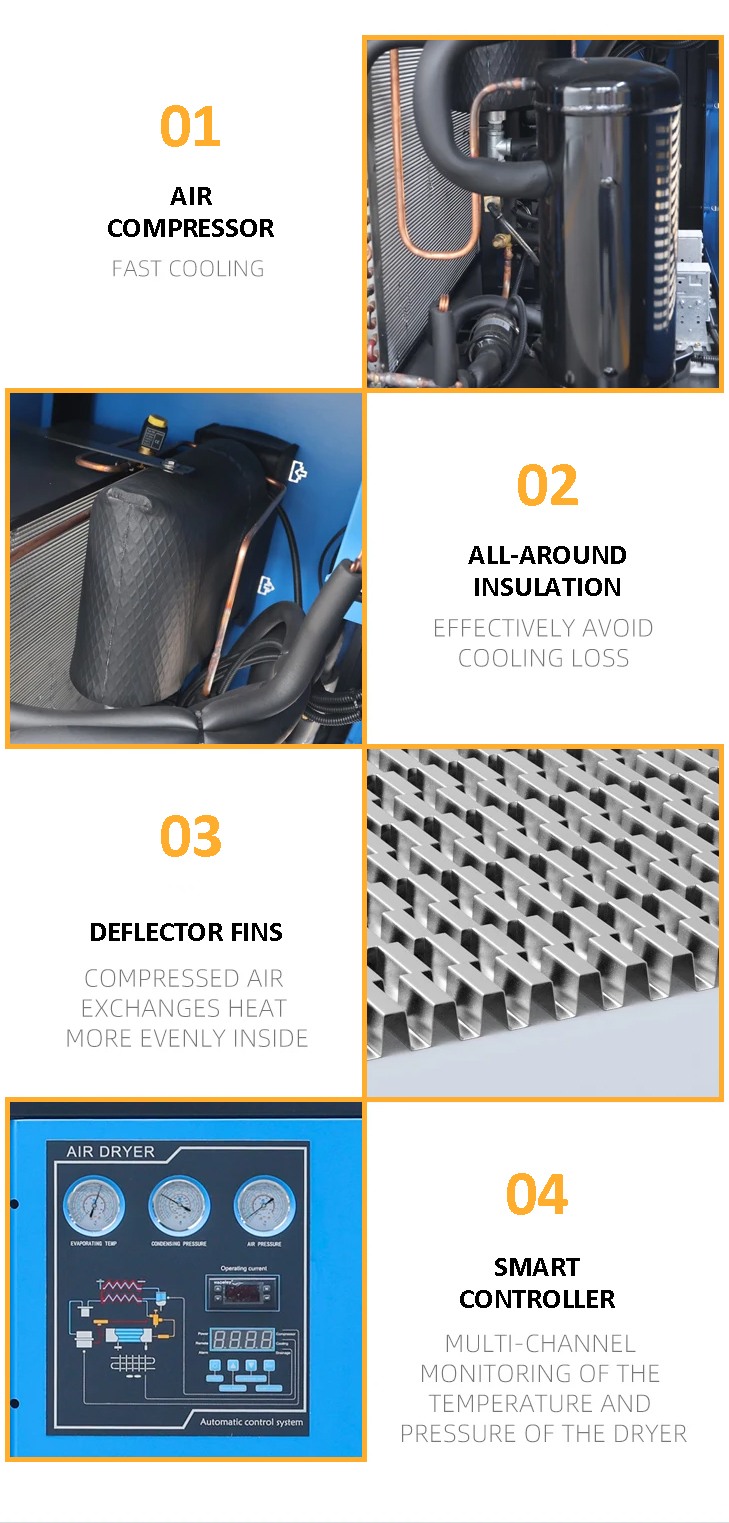

2. Product characteristics

- Adopt special design, make it small pressure difference and energy saving.

- Use thickened copper tubes to prevent corrosion and leakage of the copper tubes, extending service life.

- Using high performance heat exchanger.

- The design margin of the entire machine is increased by 20% to ensure stable operation of the unit under harsh working conditions.

- The cylinder is coated with anti-rust paint to prevent rust inside the machine.

- Use high quality parts

- The air-water separator and multiple drainage designs enable more timely and thorough drainage, avoiding the problem of poor dew point quality caused by residual moisture.

- Low-pressure protection device effectively protects compressor life and reduces maintenance costs.

| Product Name | Stainless steel air tank |

| Volume | 300-6000L; 0.3-6m³ |

| Pressure | 8-16 bar |

| Applicable Industrial | Air compressor |

| Medium | air, steam, nitrogen, oxygen, water |

| Air Inlet Temperature | ≤60℃ |

| Service Life | 10-15 years |

Air Dryer Refrigerated Air Drying Machine For Air Compressor

| Model | Compressor power (HP) | Capacity(Nm³/min) | Voltage | Weight (kg) |

| BETA005 | 0.25 | 0.8 | 220v/50hz | 50 |

| BETA010 | 0.35 | 1.8 | 1594 | 55 |

| BETA020 | 0.5 | 2.8 | 1598 | 65 |

| BETA030 | 0.75 | 3.8 | 1598 | 68 |

| BETA040 | 1.25 | 5.5 | 1905 | 90 |

| BETA060 | 1.5 | 6.8 | 1907 | 95 |

| BETA080 | 2 | 8.8 | 1909 | 130 |

| BETA100 | 2.5 | 11.5 | 1909 | 135 |

| BETA120 | 3 | 14 | 1945 | 160 |

| BETA150 | 4 | 16 | 2325 | 165 |

| BETA200 | 5 | 22.8 | 2327 | 250 |

| BETA250 | 6 | 28.5 | 2331 | 300 |

| BETA300 | 8 | 35 | 2327 | 400 |

| BETA400 | 10 | 45 | 2562 | 500 |

| BETA500 | 12.5 | 55 | 2564 | 600 |

Air Dryer Refrigerated Air Drying Machine For Air Compressor

| Model | Compressor power (HP) | Capacity(Nm³/min) | Voltage | Weight (kg) |

| BETA005 | 0.25 | 0.8 | 220v/50hz | 50 |

| BETA010 | 0.35 | 1.8 | 1594 | 55 |

| BETA020 | 0.5 | 2.8 | 1598 | 65 |

| BETA030 | 0.75 | 3.8 | 1598 | 68 |

| BETA040 | 1.25 | 5.5 | 1905 | 90 |

| BETA060 | 1.5 | 6.8 | 1907 | 95 |

| BETA080 | 2 | 8.8 | 1909 | 130 |

| BETA100 | 2.5 | 11.5 | 1909 | 135 |

| BETA120 | 3 | 14 | 1945 | 160 |

| BETA150 | 4 | 16 | 2325 | 165 |

| BETA200 | 5 | 22.8 | 2327 | 250 |

| BETA250 | 6 | 28.5 | 2331 | 300 |

| BETA300 | 8 | 35 | 2327 | 400 |

| BETA400 | 10 | 45 | 2562 | 500 |

| BETA500 | 12.5 | 55 | 2564 | 600 |