| Refrigerant: | |

|---|---|

| Pressure dew point: | |

| Inlet air temp.: | |

| Ambient temp.: | |

| Availability: | |

| Quantity: | |

Air-cooled dryer; Water-cooled dryer

BETA PLASTIC MACHINERY

8418692090

Industrial Air Dryer Refrigerated Freeze Air Drying Machine

1. Working principle

The working principle of a refrigerated air dryer involves the use of a refrigeration system to cool and dehumidify the compressed air.

The process starts with the entry of hot and moist compressed air into the air-to-air heat exchanger. Here, the incoming air is cooled down by the outgoing cold air, which helps to reduce its temperature and remove a portion of the moisture.

Next, the cooled air enters the evaporator, where it is further cooled to a temperature close to its dew point. As the air cools, the moisture in it condenses into liquid water, which is then separated from the air using an air-water separator. The separated water is drained out, while the dry air continues its journey.

The dry air then enters the air-to-refrigerant heat exchanger, where it is further cooled by the refrigerant. This helps to lower the temperature of the air and remove any remaining moisture.

Finally, the cold and dry compressed air passes through the aftercooler, where it is reheated to prevent any potential condensation in downstream equipment. The reheated air is then ready for use in various applications.

Overall, the refrigerated air dryer works by cooling and dehumidifying the compressed air, ensuring that it is free from moisture and ready for use in sensitive applications that require dry air.

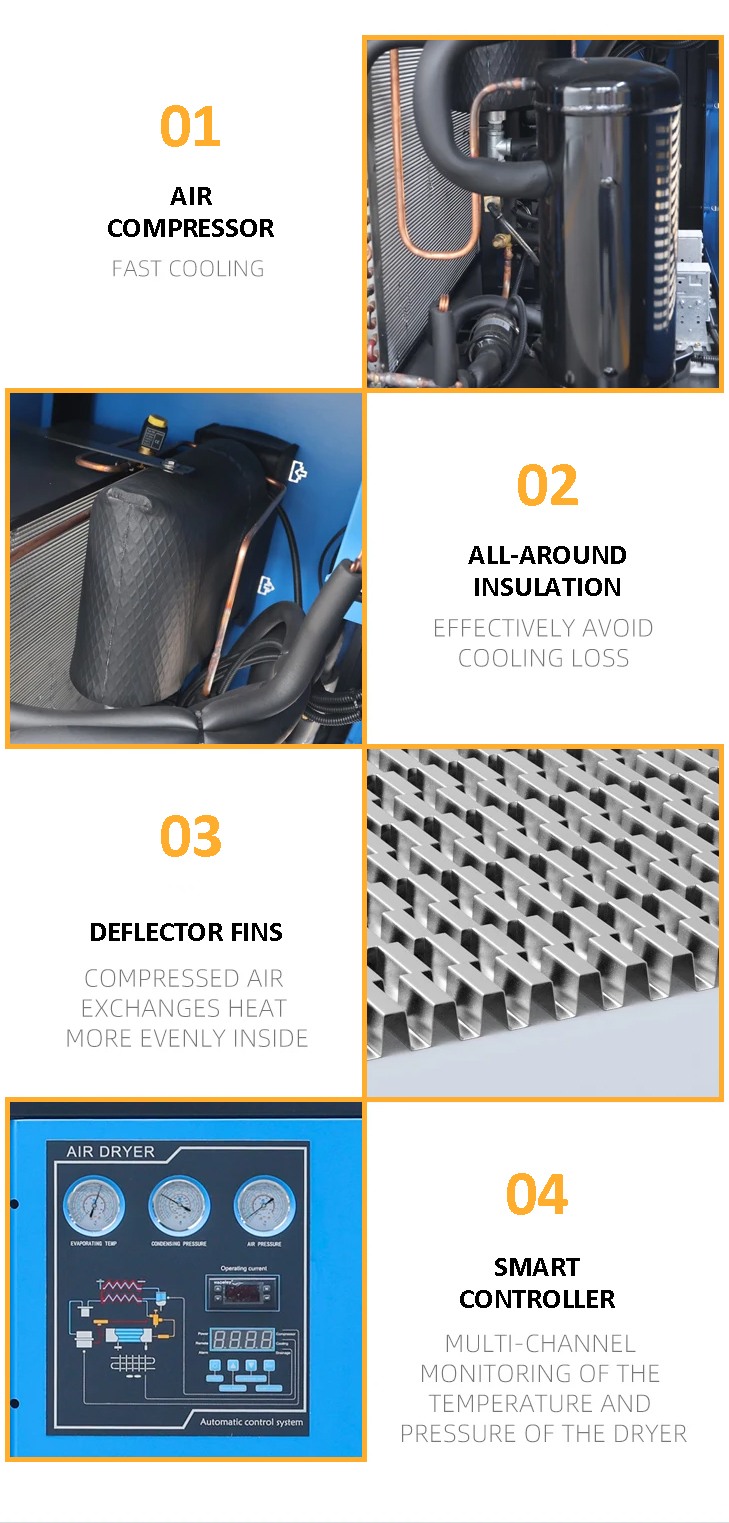

2. Product characteristics

The cold dryer, also known as the freeze dryer, offers several distinctive features that set it apart from traditional drying methods. Firstly, it utilizes a low-temperature drying process, which helps preserve the quality, flavor, and nutritional value of the dried products. This makes it an ideal choice for drying delicate or heat-sensitive items such as fruits, vegetables, herbs, and even pharmaceuticals.

Secondly, the cold dryer operates by removing moisture through sublimation, a process where water transitions directly from a solid (ice) to a gas (water vapor) without passing through the liquid phase. This unique technique ensures that the dried products retain their original shape, color, and texture, resulting in visually appealing and aesthetically pleasing end products.

Additionally, the cold dryer offers precise control over the drying parameters, such as temperature, pressure, and drying time. This allows for customization and optimization of the drying process based on the specific requirements of different products. Moreover, the machine is equipped with advanced sensors and monitoring systems to ensure consistent and uniform drying throughout the entire batch.

Furthermore, the cold dryer boasts energy efficiency and cost-effectiveness. By utilizing low temperatures and operating in a closed-loop system, it minimizes energy consumption and reduces production costs. This makes it an environmentally friendly option for businesses looking to reduce their carbon footprint and save on operational expenses.

Lastly, the cold dryer is designed for ease of use and maintenance. It features user-friendly controls, automated processes, and easy-to-clean components, making it suitable for both professional and domestic applications. With its compact size and quiet operation, it can be conveniently placed in any setting without causing disruption.

In summary, the cold dryer offers a range of benefits, including preservation of product quality, precise control over drying parameters, energy efficiency, and ease of use. These features make it an indispensable tool for various industries, including food processing, pharmaceuticals, and research laboratories.

| Product Name | Stainless steel air tank |

| Volume | 300-6000L; 0.3-6m³ |

| Pressure | 8-16 bar |

| Applicable Industrial | Air compressor |

| Medium | air, steam, nitrogen, oxygen, water |

| Air Inlet Temperature | ≤60℃ |

| Service Life | 10-15 years |

Industrial Air Dryer Refrigerated Freeze Air Drying Machine

1. Working principle

The working principle of a refrigerated air dryer involves the use of a refrigeration system to cool and dehumidify the compressed air.

The process starts with the entry of hot and moist compressed air into the air-to-air heat exchanger. Here, the incoming air is cooled down by the outgoing cold air, which helps to reduce its temperature and remove a portion of the moisture.

Next, the cooled air enters the evaporator, where it is further cooled to a temperature close to its dew point. As the air cools, the moisture in it condenses into liquid water, which is then separated from the air using an air-water separator. The separated water is drained out, while the dry air continues its journey.

The dry air then enters the air-to-refrigerant heat exchanger, where it is further cooled by the refrigerant. This helps to lower the temperature of the air and remove any remaining moisture.

Finally, the cold and dry compressed air passes through the aftercooler, where it is reheated to prevent any potential condensation in downstream equipment. The reheated air is then ready for use in various applications.

Overall, the refrigerated air dryer works by cooling and dehumidifying the compressed air, ensuring that it is free from moisture and ready for use in sensitive applications that require dry air.

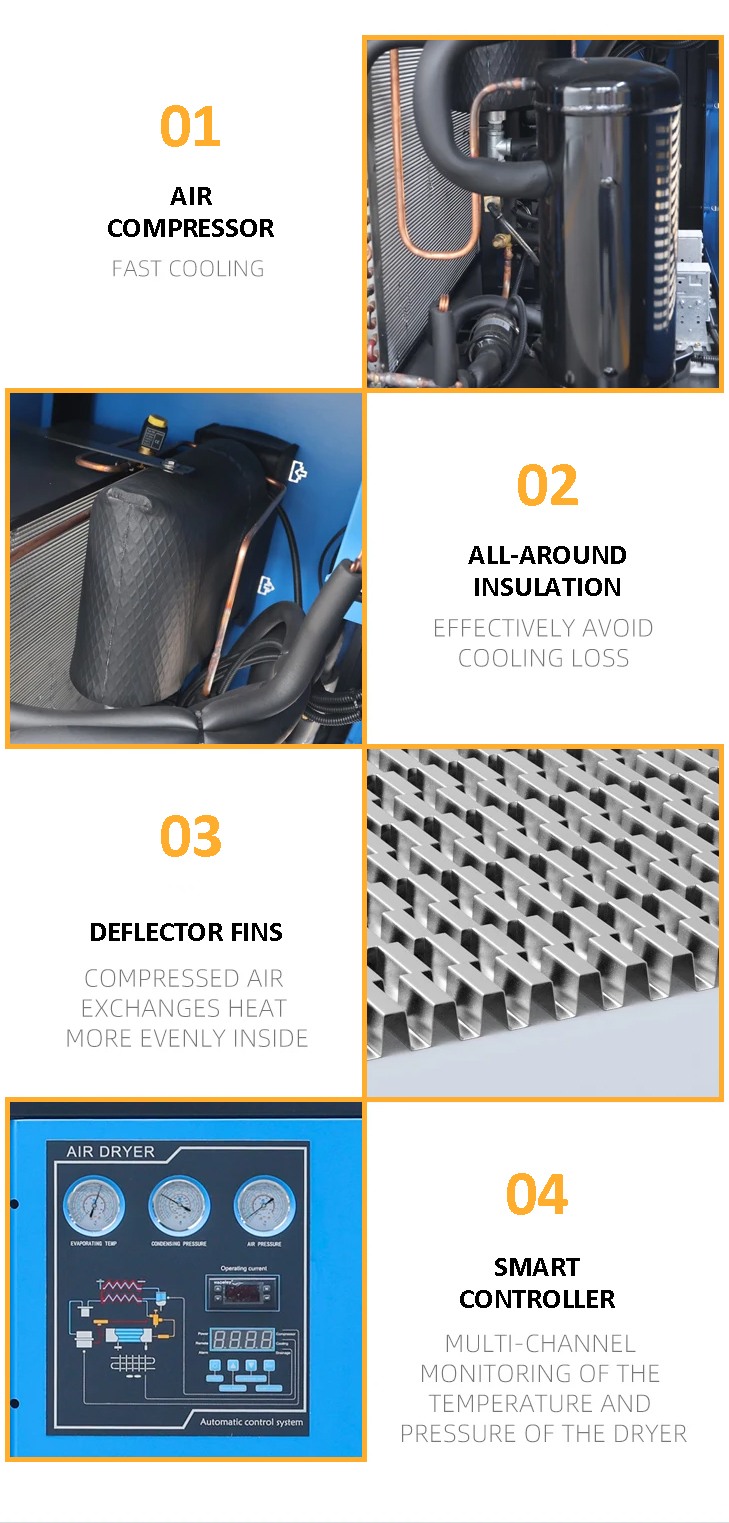

2. Product characteristics

The cold dryer, also known as the freeze dryer, offers several distinctive features that set it apart from traditional drying methods. Firstly, it utilizes a low-temperature drying process, which helps preserve the quality, flavor, and nutritional value of the dried products. This makes it an ideal choice for drying delicate or heat-sensitive items such as fruits, vegetables, herbs, and even pharmaceuticals.

Secondly, the cold dryer operates by removing moisture through sublimation, a process where water transitions directly from a solid (ice) to a gas (water vapor) without passing through the liquid phase. This unique technique ensures that the dried products retain their original shape, color, and texture, resulting in visually appealing and aesthetically pleasing end products.

Additionally, the cold dryer offers precise control over the drying parameters, such as temperature, pressure, and drying time. This allows for customization and optimization of the drying process based on the specific requirements of different products. Moreover, the machine is equipped with advanced sensors and monitoring systems to ensure consistent and uniform drying throughout the entire batch.

Furthermore, the cold dryer boasts energy efficiency and cost-effectiveness. By utilizing low temperatures and operating in a closed-loop system, it minimizes energy consumption and reduces production costs. This makes it an environmentally friendly option for businesses looking to reduce their carbon footprint and save on operational expenses.

Lastly, the cold dryer is designed for ease of use and maintenance. It features user-friendly controls, automated processes, and easy-to-clean components, making it suitable for both professional and domestic applications. With its compact size and quiet operation, it can be conveniently placed in any setting without causing disruption.

In summary, the cold dryer offers a range of benefits, including preservation of product quality, precise control over drying parameters, energy efficiency, and ease of use. These features make it an indispensable tool for various industries, including food processing, pharmaceuticals, and research laboratories.

| Product Name | Stainless steel air tank |

| Volume | 300-6000L; 0.3-6m³ |

| Pressure | 8-16 bar |

| Applicable Industrial | Air compressor |

| Medium | air, steam, nitrogen, oxygen, water |

| Air Inlet Temperature | ≤60℃ |

| Service Life | 10-15 years |

Industrial Air Dryer Refrigerated Freeze Air Drying Machine

| Model | Compressor power (HP) | Capacity(Nm³/min) | Voltage | Weight (kg) |

| BETA005 | 0.25 | 0.8 | 220v/50hz | 50 |

| BETA010 | 0.35 | 1.8 | 1594 | 55 |

| BETA020 | 0.5 | 2.8 | 1598 | 65 |

| BETA030 | 0.75 | 3.8 | 1598 | 68 |

| BETA040 | 1.25 | 5.5 | 1905 | 90 |

| BETA060 | 1.5 | 6.8 | 1907 | 95 |

| BETA080 | 2 | 8.8 | 1909 | 130 |

| BETA100 | 2.5 | 11.5 | 1909 | 135 |

| BETA120 | 3 | 14 | 1945 | 160 |

| BETA150 | 4 | 16 | 2325 | 165 |

| BETA200 | 5 | 22.8 | 2327 | 250 |

| BETA250 | 6 | 28.5 | 2331 | 300 |

| BETA300 | 8 | 35 | 2327 | 400 |

| BETA400 | 10 | 45 | 2562 | 500 |

| BETA500 | 12.5 | 55 | 2564 | 600 |

Industrial Air Dryer Refrigerated Freeze Air Drying Machine

| Model | Compressor power (HP) | Capacity(Nm³/min) | Voltage | Weight (kg) |

| BETA005 | 0.25 | 0.8 | 220v/50hz | 50 |

| BETA010 | 0.35 | 1.8 | 1594 | 55 |

| BETA020 | 0.5 | 2.8 | 1598 | 65 |

| BETA030 | 0.75 | 3.8 | 1598 | 68 |

| BETA040 | 1.25 | 5.5 | 1905 | 90 |

| BETA060 | 1.5 | 6.8 | 1907 | 95 |

| BETA080 | 2 | 8.8 | 1909 | 130 |

| BETA100 | 2.5 | 11.5 | 1909 | 135 |

| BETA120 | 3 | 14 | 1945 | 160 |

| BETA150 | 4 | 16 | 2325 | 165 |

| BETA200 | 5 | 22.8 | 2327 | 250 |

| BETA250 | 6 | 28.5 | 2331 | 300 |

| BETA300 | 8 | 35 | 2327 | 400 |

| BETA400 | 10 | 45 | 2562 | 500 |

| BETA500 | 12.5 | 55 | 2564 | 600 |